1、 Types and Trends of Electric Motors for New Energy Vehicles

(1) The structure and performance of the motor

The drive motor system is one of the three core components of Alternative fuel vehicle. The motor drive control system is the main execution structure in the operation of new energy vehicles, and its driving characteristics determine the main performance indicators of vehicle operation. It is an important component of electric vehicles. The entire drive system of an electric vehicle includes two parts: the electric motor drive system and its mechanical transmission mechanism. The motor drive system is mainly composed of electric motors, power converters, controllers, various detection sensors, and power supplies.

Simply put, the motor drive system mainly consists of two parts: the driving motor and the motor controller. From the perspective of the industrial value chain of motor drive systems, the cost ratio of driving motors and motor controllers is roughly the same.

The drive motor of new energy vehicles belongs to the category of medium and low voltage motors. Due to the particularity of its application field, it has higher performance requirements than ordinary medium and low voltage products:

1) Wide speed regulation range: New energy vehicles have two types of operating conditions, requiring them to operate in the constant torque range during startup, acceleration, and hill climbing; When driving at high speeds, the motor is required to operate in a constant power range;

2) The high power density is mainly aimed at increasing the range of the vehicle while minimizing internal space limitations and battery power;

3) Safe and reliable, requiring stable operation and excellent seismic and heat dissipation performance of the motor;

4) Lightweight, which means the motor has a small volume and meets the requirements of lightweight for the entire vehicle;

5) Strong overload capacity: Under starting, accelerating, and climbing conditions, the motor is required to have 4-5 times the overload capacity.

(2) There are differences in application scenarios for different motor types

Motors are generally required to have two functions: electric and power generation. According to the type, several types of motors can be selected, including DC, AC, permanent magnet brushless or switched reluctance motors. The power converter is available in the form of DC/DC power converter, DC/AC power converter, etc. according to the selected motor type. Its function is to convert the direct current of the battery into a corresponding voltage level DC, AC, or pulse power supply according to the driving current requirements of the selected motor.

The driving motors suitable for new energy vehicles mainly include permanent magnet synchronous, AC asynchronous, and switched reluctance. Due to their different characteristics, they have different application scenarios.

Permanent magnet synchronous motors have small size, light weight, high power density, high reliability, high speed regulation accuracy, and fast response speed; But the high-power is lower and the cost is higher. Due to the high power density of permanent magnet synchronous motors, their work efficiency can reach up to 97%, and they can output large power and acceleration for vehicles. Therefore, they are mainly used in new energy passenger vehicles with high energy to volume requirements.

Low price and reliable operation of AC asynchronous motors; However, its low power density, complex control, and small speed range are inherent limitations. The price advantage makes it widely used in new energy buses.

Switched reluctance motor has low price, simple and reliable circuit, and wide speed range; But the vibration and noise are high, the control system is complex, and it will generate a large pulse current on the DC power supply. Used for large passenger cars.

The current development direction of new energy vehicle drive motors includes the following aspects: small and lightweight; Sex; Better torque characteristics; Long service life and high reliability; Low noise; The price is low. Over time, the development of new energy driven motors has shown the following trends:

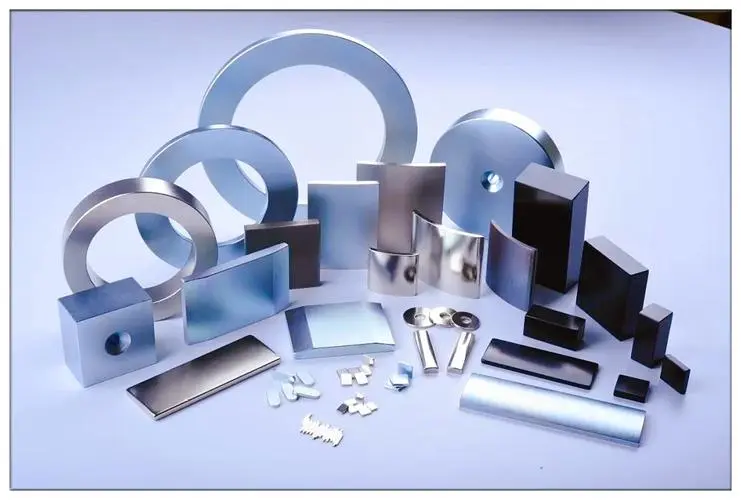

① Permanent magnetization of the motor body: Permanent magnet motors have advantages such as high torque density, high power density, high efficiency, and high reliability. China has abundant rare earth resources, so high-performance permanent magnet motors are an important development direction for automotive drive motors in China.

② Digitization of motor control: The emergence of specialized chips and digital signal processors has promoted the digitization of motor controllers, improved the control accuracy of motor systems, and effectively reduced system volume.

③ Motor system integration: Through electromechanical integration (motor engine integration or motor gearbox integration) and controller integration, it is beneficial to reduce the weight and volume of the drive system and effectively reduce system manufacturing costs.

(3) Permanent magnet synchronous motors are becoming the mainstream trend

At present, AC asynchronous motors are mainly used by American car companies led by Tesla and some European companies. On the one hand, this is related to Tesla's initial technological path choice, as AC induction motors are cheap and their larger size does not hinder American cars; On the other hand, the United States has a well-developed highway network, and the efficiency and performance of AC motors in high-speed sections are excellent.

Permanent magnet synchronous motors are still widely used in new energy vehicle motors in other countries, including Japan. The suitability for domestic road conditions is the main factor, and the permanent magnet synchronous motor can still maintain a relatively high speed during repeated start stop, acceleration and deceleration, making it a choice for conditions with limited high-speed road networks. In addition, China has abundant rare earth reserves, and the supporting foundation of Japan's rare earth permanent magnet industry is also an important factor. At present, the proportion of permanent magnet synchronous motors used in new energy vehicles in China exceeds 90%.

Japanese car companies such as Toyota, Honda, and Nissan mostly use permanent magnet synchronous motor drive systems, such as Toyota's Prius and Honda's CIVIC. Because there are many companies supplying Rare-earth magnet for permanent magnet motors in Japan, and most cars are driven at medium and low speeds, it is appropriate to use permanent magnet synchronous motors with high efficiency during acceleration and deceleration.

China

China English

English