(1) Current Development Status of Foreign Industries

In 1983, neodymium iron boron was successively invented in Japan and the United States, and was rapidly promoted and developed due to its superior magnetic properties and low price. In the 1980s and 1990s, companies such as Sumitomo, Shinyue Chemical, and Tokyo Electric (TDK) successively produced sintered neodymium iron boron, with global production capacity mainly concentrated in Japan and the United States.

Since the 21st century, influenced by factors such as resources and costs, developed economies represented by the United States and Europe have embarked on industrial adjustments, and the global sintered neodymium iron boron industry has rapidly shifted to China; Meanwhile, since the beginning of this century, with significant breakthroughs made by China in technologies such as rare earth separation and preparation of rare earth permanent magnet materials, the manufacturing of rare earth permanent magnet materials has rapidly caught up with international advanced levels. The foreign rare earth permanent magnet material industry has begun to significantly shrink, and neodymium iron boron production lines in the United States, Europe, and other countries have gradually shut down, shifting towards imports from China.

As of now, foreign sintering neodymium iron boron production enterprises with a certain scale mainly include Japan's Shin Yue Chemical, Hitachi Metals (Neomax), TDK, and Germany's VAC5.

(2) Current Situation of Industry Development in China

China's rare earth reserves are globally leading, with a complete range of light and heavy rare earth varieties, laying the foundation for the development of the rare earth permanent magnet material industry. In 1984, the joint action team of the Chinese Academy of Sciences and the Ministry of Metallurgy carried out the development of sintered Nd-Fe-B, rapidly improving the magnetic energy product and keeping pace with the Vanguard International Semiconductor Corporation level. In 1985, Beijing Sanhuan New Materials High tech Company (now Zhongke Sanhuan) was established, marking the beginning of the industrialization process of China's rare earth permanent magnet material industry. In 1986, Ningbo Sanhuan Magnetic Factory (now Ningbo Koningda Industrial Co., Ltd.) was completed and put into operation, marking the official start of mass production of sintered neodymium iron boron in China.

At present, the main development characteristics of China's rare earth permanent magnet material industry include:

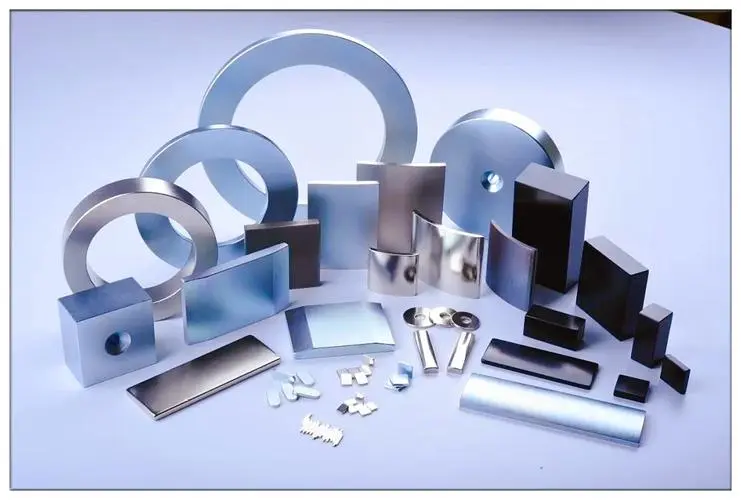

① Sintered neodymium, iron, and boron dominate, with continuous growth in production

Sintered neodymium iron boron plays a leading role in the total production of neodymium iron boron. According to data from the China Rare Earth Industry Association, the production of sintered neodymium iron boron blanks in China in the first half of 2022 was 116000 tons, accounting for 95.10% of the rare earth permanent magnet materials of that year. Bonded neodymium iron boron accounted for 3.68%, while other permanent magnet materials accounted for only 1.22% in total.

Since the 21st century, China's neodymium iron boron production has gone through four growth stages: firstly, from 2002 to 2007, driven by rapid demand penetration, the production increased from 17000 tons in 2003 to 50000 tons in 2007. In 2008, due to the global financial crisis, production declined. Secondly, from 2009 to 2011, the domestic economic recovery led to an increase in demand for neodymium iron boron, and production returned to the growth track. In 2011, the production increased to around 90000 tons. Subsequently, national policy regulation led to a significant increase in rare earth prices and a slowdown in the growth of neodymium iron boron production. Thirdly, from 2014 to 2015, the prices of rare earths decreased, and downstream industries such as energy-saving elevators, wind power generation, and automobiles rapidly released demand. The production of neodymium, iron, and boron increased rapidly. Fourthly, from 2016 to 2021, China's economic development stabilized, and the production of neodymium, iron, and boron also entered a stage of steady growth.

② The market competition for mid to low performance products is fierce, and there is still room for growth in high-performance products

At the beginning of this century, due to the low production threshold of medium and low performance rare earth permanent magnet materials, a large number of small and medium-sized enterprises have put into production. Their technological level and independent innovation ability are insufficient, and their products are severely homogenized with low technological content. They mainly rely on labor costs and environmental protection costs to compete for the market. At present, the Gross margin of small and medium-sized enterprises in China, which mainly focus on medium and low performance rare earth permanent magnetic materials, is low. Their products are concentrated in magnetic adsorption, magnetic separation, electric bicycles, audio equipment, and even primary application fields such as luggage buckles, door buckles, toys, and the market competition is fierce.

As of now, from the global market to the domestic market, rare earth permanent magnet materials have shown the characteristics of excessive supply of medium and low performance, and insufficient supply of high performance. Taking sintered neodymium iron boron as an example, according to data from the China Rare Earth Industry Association and Frost&Sullivan, the high-performance neodymium iron boron production in 2020 was 46200 tons, accounting for only 24%.

In recent years, China's electronic information, digital communications, new energy vehicles, wind power generation, energy-saving household appliances, medical equipment, Arms industry and other frontier fields have developed rapidly. As a key strategic material for the aforementioned industries to play the role of electromagnetic conversion, electrical signal conversion, magnetic force conversion and other functions, rare earth permanent magnetic materials have seen growing market demand. With the improvement of downstream application requirements, the performance and quality of sintered neodymium iron boron products in China have also been significantly improved. Taking the N series as an example, it has gradually developed from low to medium grade products below N40 to high grade products such as N54.

In the future, with the advancement of carbon neutrality in the global market, cutting-edge and emerging fields such as new energy vehicles, wind power generation, industrial motors, energy-saving household appliances, and 3C consumer electronics will continue to grow. The application scenarios of high-performance and high-quality rare earth permanent magnet materials will continue to expand and deepen, and leading enterprises with strong research and development, production, and supporting service capabilities will gain broader development space.

③ Significant trend of industrial clustering

After more than 20 years of development and agglomeration, China's rare earth permanent magnet material enterprises have shown obvious industrial clustering characteristics. Currently, their production capacity is mainly distributed in the Beijing Tianjin region, Zhejiang Ningbo region, Shanxi region, Baotou region, Ganzhou region, Shandong region, etc., forming several major industrial clusters.

Compared to regions such as Shanxi, Tianjin, Baotou, and Ganzhou, the rare earth permanent magnet material industry in Ningbo started earlier and has a larger scale. According to the statistics of the China Rare Earth Industry Association, in 2019, the production of sintered neodymium iron boron in Ningbo accounted for approximately 38.9% of the national total. Relying on the technical advantages brought by the Chinese Academy of Sciences Ningbo Institute of Materials Technology and Engineering and other scientific research institutes, the market advantages of itself as a good port in East China, as well as the more developed private economy and more active market mechanism, the development of the industrial chain in Ningbo is relatively mature, especially the mechanical processing and surface treatment related to the manufacturing of sintered NdFeB finished products. In contrast, the rare earth permanent magnet material industry in Ganzhou region is an industrial cluster formed by relying on the advantages of rare earth resources, with products more inclined towards the front end of the rare earth permanent magnet material industry chain, such as semi-finished rare earth permanent magnet materials such as neodymium iron boron rapid solidification thin sheets.

Baotou is known as the "Capital of Rare Earth", with its proven rare earth resource reserves and production ranking first in the country. It has also developed into an important rare earth permanent magnet material industry cluster in the country. In the early stages of industrial development, the Baotou area mainly focused on raw materials and primary products, while the development of downstream industries such as rare earth new materials and high-end applications was relatively insufficient. In recent years, relying on China China Northern Rare Earth (Group) High tech Co., Ltd. and other rare earth raw material leaders, and the four rare earth research institutes represented by Baotou Rare Earth Research Institute, Shanghai Jiaotong University Baotou Materials Research Institute, Chinese Academy of Sciences Baotou Rare Earth R&D Center, and Inner Mongolia Rare Earth Functional Materials Innovation Center, Baotou has formed a system of production, learning, research and application from rare earth mining, beneficiation, smelting, deep processing to downstream product research, development A well-established rare earth industry chain with complete production facilities, including production of rare earth permanent magnet material blanks, mechanical processing, surface treatment, and corresponding market trade channels, has become an important rare earth permanent magnet material base and even a rare earth industry base in China.

In addition, the local government of Baotou attaches great importance to the large-scale and intensive development of relevant industries. In recent years, it has successively issued several industrial incentive measures such as the Opinions of the People's Government of Baotou City on Further Accelerating the Development of Rare Earth Industry, and the Supporting Policies and Measures for Rare Earth New Material Production Enterprises in Baotou City, creating a good policy environment for the development of rare earth permanent magnetic material industry. Tianhe Magnetic entered Baotou in 2008, and was recognized by the Inner Mongolia Rare Earth Industry Association as the rare-earth permanent magnetic material enterprise with the strongest comprehensive strength in the autonomous region and the enterprise with the highest market share of Nd-Fe-B in the autonomous region in 2020. With the continuous improvement of industrial chain supporting facilities and strong support from local policies, enterprises such as Jiangxi Jinli Permanent Magnet and Anhui Dadi Bear have also settled and built factories.

④ Unclear cyclical and seasonal characteristics

The rare earth permanent magnet material industry mainly fluctuates with downstream industries. Although the development cycles of downstream industries are different, they generally fluctuate with macroeconomic cycles. With the development of global green economy and Low-carbon economy, as well as the gradual implementation of China's goals of "2030 carbon peak" and "2060 carbon neutral", the main downstream industries of rare earth permanent magnetic materials have good prospects for development. Therefore, the fluctuation in the development prospects of the rare earth permanent magnet material industry due to the impact of economic cycles is not significant.

At present, the downstream markets of high-performance sintered neodymium iron boron in China mainly include wind power generation, energy-saving variable frequency air conditioning, new energy vehicles and automotive components, energy-saving elevators, 3C consumer electronics, etc. Except for the obvious seasonal characteristics of wind power generation (winter is the off-season for installation), other downstream markets have weaker seasonal characteristics. Overall, there are no obvious seasonal characteristics in China's rare earth permanent magnet material industry.

China

China English

English